Phone: 800-362-6533 • Local: 330-497-9650 • Fax: 330-497-0415

7800 Freedom Avenue NW • North Canton, Ohio 44720-6978

sales@specialtyhose.com | Cage Code 1S353

© 2024 Specialty Hose Corporation | All Rights Reserved

Website design and hosting by EmTech Enterprises

We accept the following

Aircraft hose assemblies that are located partially or totally in "Fire Zones" must have fire protection.

It is a good idea to provide fire protection for any hose that is located in proximity to any exhaust carrying component.

An interesting example is in the Piper Cherokee aircraft where Piper routed the hose next to the exhaust system.

Firesleeve does not raise the temperature rating of the hose - it provides fire protection only. In the event of a fire it

guarantees the hose will not fail for a minimum of 15 minutes when exposed to direct flame. It is engineered to give a

pilot a short window to get the aircraft on the ground before failed hoses compound a potential lethal situation. In tight

engine compartments one must also keep the hose away from the exhaust system. A hose in direct contact with the

exhaust system will be exposed to excessive temperature and could fail.

Firesleeve, especially the integral type firesleeve provides some chafe protection for the hose.

Firesleeve should be cut a little longer than the hose, especially for larger diameter hoses or hoses with bends.

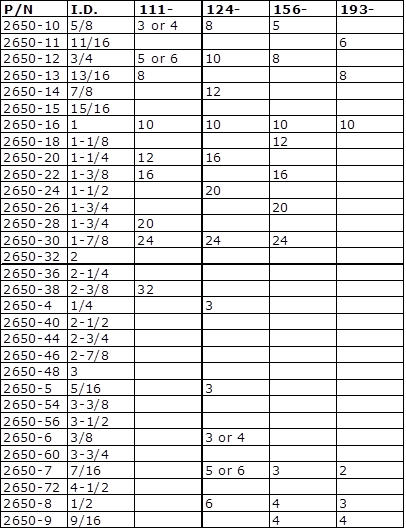

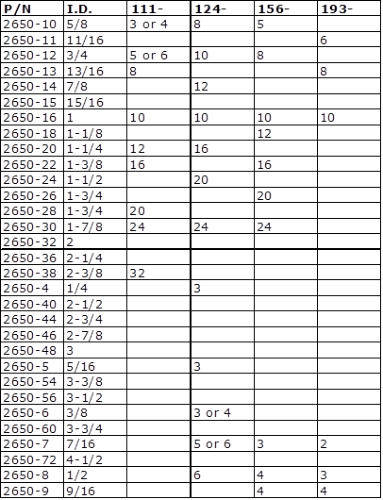

The firesleeve application chart below shows what size firesleeve to use. Firesleeve part number is AE102-size.

Fire Protection & Fire Sleeving

CERTIFIED WELDING

SECTION IX ANSI B31.1 / B31.3

AWS D17.1

For additional information regarding our hose products, please contact us.

•

Firesleeve clamps require a pulling tool.

•

We recommend you seal the end of the firesleeve with End Dip (AE13702-003). This

prevents any fluids from wicking into the firesleeve, and improves appearance.

•

Firesleeve should extend slightly (1/8 inch) beyond fitting socket but not interfere with

free nut rotation. This extension helps shield the fitting in case of fire.

On this hose, the Firesleeve was cut too short and slipped back when the hose was bent during installation. Always cut the

firesleeve slightly longer than the hose. The larger the hose diameter or the more bend in the hose, the longer the

firesleeve.

Fire Sleeve Clamps

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

303 -

666 -

701 -

306 -

SPECIALTY HOSE

CORPORATION

Phone: 800-362-6533 • Fax: 330-497-0415

7800 Freedom Avenue NW • North Canton, Ohio 44720-6978

sales@specialtyhose.com | Cage Code 1S353

© 2023 Specialty Hose Corporation | All Rights Reserved

Website design and hosting by EmTech Enterprises

For additional information regarding our hose products, please contact us.

- Products

- Applications

- Technical Information

- STAMPED

- Metal Hose Installation Guide

- Pressure Derating vs Temp

- Decimal Equivalent

- Thermal Expansion of Pipe

- Metric Conversion Factors

- Pipe Anchoring & Guiding

- Metal Hose Selection Factors

- Metal Hose Assembly Length Tolerances

- Metal Hose End Fitting Guide

- PTFE Hose End Fitting Guide

- Chemical Compatibility Chart

- Expansion Joint Information

- Effusion/Corrosion

- Send RFQ

- About Industrial

- Aircraft Hose Store

- For Aircraft Owners

- For FBO/Mechanics

- Hose Kits

- Aircraft Hose Lookup

- Products

- PTFE Hose

- 666 Aluminum Fittings

- 666 Crimp Fittings

- 666 Reuseable Fittings Eng Bulletin

- AE246 Hi Pressure Hose Crimp

- AE246 Hi Pressure Hose Reusable

- AE313 Spiral Reinf Hose Eng Bulletin

- AE318 Wire Braid Hose Eng Bulletin

- AE645 Teflon Hose Eng Bulletin

- Brown Silicone Firesleeve Hose Eng Bulletin

- Convoluted Teflon Hose Eng Bulletin

- Firesleeve

- Rubber Hose

- Aircraft Metal Hose

- Other Hose Products

- Quick Disconnect Coupling

- 155-145 Series Coupling Catalog

- 3200 Series Coupling Catalog

- AA40 - 3900 Series Quick-Disconnect Coupling

- AEB189 - Self Sealing Coupling for Modular Hydralic Systems

- Break-away Coupling Catalog

- Ground Support Coupling Catalog

- Low Profile Couplings Catalog

- Low Profile Self Sealing Coupling Catalog

- Push-Pull Coupling Catalog

- TF100-32 Std Tube Sz and Variable Dia V-Band Coup

- Ultra-Mate TF100-5A

- Clamps, V Bands and Flanges

- AA29 - Aircraft Band Clamps

- AA33 - Stainless Steel Straps

- AEB195 - J13 and WJ13 Gasketless Tubes

- AEB197A - Conoseal (TM) Joints, Fittings and Conomate (TM) Couplings

- AEB201 - Exhaust Clamps

- AEB211 - LJ11 and J11 Joints

- DS100-6 - Exhaust Clamps

- TF100-26 - Aircraft Band Clamps

- TF100-27 - Stainless Steel Straps

- TF100-28 - J13 and WJ13 Gasketless Tubes

- TF100-30 - LJ11 and J11 Joints

- TF100-32 - Std Tube Sz and Variable Dia V-Band Coup

- PTFE Hose

- Markets

- Technical Information

- Cross-Reference

- About Aerospace

Aircraft hose assemblies that are located partially or totally in

"Fire Zones" must have fire protection.

It is a good idea to provide fire protection for any hose that is

located in proximity to any exhaust carrying component. An

interesting example is in the Piper Cherokee aircraft where

Piper routed the hose next to the exhaust system.

Firesleeve does not raise the temperature rating of the hose - it

provides fire protection only. In the event of a fire it guarantees

the hose will not fail for a minimum of 15 minutes when exposed

to direct flame. It is engineered to give a pilot a short window to

get the aircraft on the ground before failed hoses compound a

potential lethal situation. In tight engine compartments one

must also keep the hose away from the exhaust system. A hose

in direct contact with the exhaust system will be exposed to

excessive temperature and could fail.

Firesleeve, especially the integral type firesleeve provides some

chafe protection for the hose.

Firesleeve should be cut a little longer than the hose, especially

for larger diameter hoses or hoses with bends.

The firesleeve application chart below shows what size

firesleeve to use. Firesleeve part number is AE102-size.

Fire Protection & Fire Sleeving

•

Firesleeve clamps require a

pulling tool.

•

We recommend you seal

the end of the firesleeve

with End Dip (AE13702-

003). This prevents any

fluids from wicking into the

firesleeve, and improves

appearance.

•

Firesleeve should extend slightly (1/8 inch) beyond fitting

socket but not interfere with free nut rotation. This

extension helps shield the fitting in case of fire.

On this hose, the Firesleeve was cut too short and slipped

back when the hose was bent during installation. Always cut

the firesleeve slightly longer than the hose. The larger the

hose diameter or the more bend in the hose, the longer the

firesleeve.

Fire Sleeve Clamps

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

AE102

303 -

666 -

701 -

306 -

- Products

- Applications

- Technical Information

- STAMPED

- Metal Hose Installation Guide

- Pressure Derating vs Temp

- Decimal Equivalent

- Thermal Expansion of Pipe

- Metric Conversion Factors

- Pipe Anchoring & Guiding

- Metal Hose Selection Factors

- Metal Hose Assembly Length Tolerances

- Metal Hose End Fitting Guide

- PTFE Hose End Fitting Guide

- Chemical Compatibility Chart

- Expansion Joint Information

- Effusion/Corrosion

- Send RFQ

- About Industrial

- Aircraft Hose Store

- For Aircraft Owners

- For FBO/Mechanics

- Hose Kits

- Eaton Product Search

- Products

- PTFE Hose

- 666 Aluminum Fittings

- 666 Crimp Fittings

- 666 Reuseable Fittings Eng Bulletin

- AE246 Hi Pressure Hose Crimp

- AE246 Hi Pressure Hose Reusable

- AE313 Spiral Reinf Hose Eng Bulletin

- AE318 Wire Braid Hose Eng Bulletin

- AE645 Teflon Hose Eng Bulletin

- Brown Silicone Firesleeve Hose Eng Bulletin

- Convoluted Teflon Hose Eng Bulletin

- Firesleeve

- Rubber Hose

- Aircraft Metal Hose

- Other Hose Products

- Quick Disconnect Coupling

- 155-145 Series Coupling Catalog

- 3200 Series Coupling Catalog

- AA40 - 3900 Series Quick-Disconnect Coupling

- AEB189 - Self Sealing Coupling for Modular Hydralic Systems

- Break-away Coupling Catalog

- Ground Support Coupling Catalog

- Low Profile Couplings Catalog

- Low Profile Self Sealing Coupling Catalog

- Push-Pull Coupling Catalog

- TF100-32 Std Tube Sz and Variable Dia V-Band Coup

- Ultra-Mate TF100-5A

- Clamps, V Bands and Flanges

- AA29 - Aircraft Band Clamps

- AA33 - Stainless Steel Straps

- AEB195 - J13 and WJ13 Gasketless Tubes

- AEB197A - Conoseal (TM) Joints, Fittings and Conomate (TM) Couplings

- AEB201 - Exhaust Clamps

- AEB211 - LJ11 and J11 Joints

- DS100-6 - Exhaust Clamps

- TF100-26 - Aircraft Band Clamps

- TF100-27 - Stainless Steel Straps

- TF100-28 - J13 and WJ13 Gasketless Tubes

- TF100-30 - LJ11 and J11 Joints

- TF100-32 - Std Tube Sz and Variable Dia V-Band Coup

- PTFE Hose

- Markets

- Technical Information

- Cross-Reference

- About Aerospace

SPECIALTY HOSE

CORPORATION

800-362-6533

Mon-Fri 8am-5pm EST

Hose Experts Standing By