Phone: 800-362-6533 • Local: 330-497-9650 • Fax: 330-497-0415

7800 Freedom Avenue NW • North Canton, Ohio 44720-6978

sales@specialtyhose.com | Cage Code 1S353

© 2024 Specialty Hose Corporation | All Rights Reserved

Website design and hosting by EmTech Enterprises

We accept the following

Measuring and Gaging

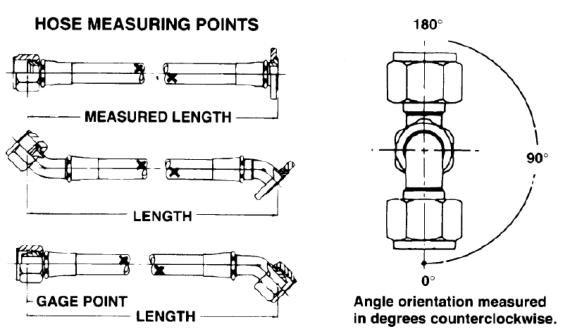

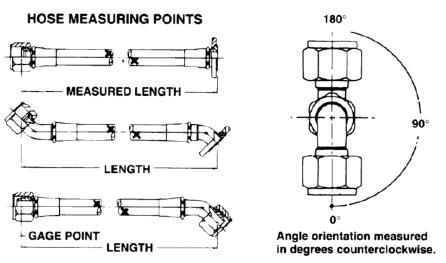

Use seat-to-seat versus Overall Method because the nuts will move and change the measured length.

Use the center line of fitting gage point on elbow fittings.

Orientation – Hold hose in front of you with near elbow pointing down towards six o’clock. Measure counter-

clockwise to rear fitting position.

Example: Rear fitting pointing at 9 o’clock is 270 degrees.

Fitting Size

Caution: Measure both ends! Hose fitting size may differ from one end to the other

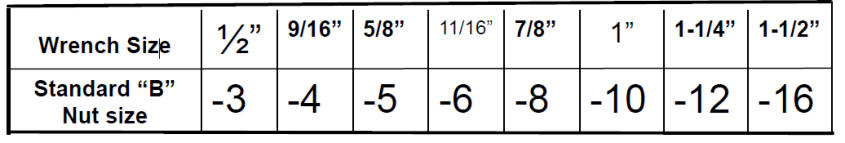

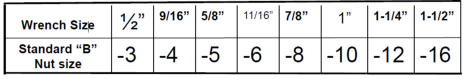

If you don’t have a thread gage, a hex wrench can be used to help identify the fitting nut size.

Measuring Aircraft Hose

CERTIFIED WELDING

SECTION IX ANSI B31.1 / B31.3

AWS D17.1

For additional information regarding our hose products, please contact us.

Hose Size

Teflon hose and some rubber hose is measured as tube size not true inside diameter. The hose is specified by

the outside diameter of the tubing. A size -6 medium pressure Teflon hose is a nominal 3/8” with a .298 ID. The

difference is important for critical flow applications such as a turbo injector lubrication line. Always check with

the manufacturer of the equipment before changing hose types.

SPECIALTY HOSE

CORPORATION

Phone: 800-362-6533 • Fax: 330-497-0415

7800 Freedom Avenue NW • North Canton, Ohio 44720-6978

sales@specialtyhose.com | Cage Code 1S353

© 2023 Specialty Hose Corporation | All Rights Reserved

Website design and hosting by EmTech Enterprises

For additional information regarding our hose products, please contact us.

- Products

- Applications

- Technical Information

- STAMPED

- Metal Hose Installation Guide

- Pressure Derating vs Temp

- Decimal Equivalent

- Thermal Expansion of Pipe

- Metric Conversion Factors

- Pipe Anchoring & Guiding

- Metal Hose Selection Factors

- Metal Hose Assembly Length Tolerances

- Metal Hose End Fitting Guide

- PTFE Hose End Fitting Guide

- Chemical Compatibility Chart

- Expansion Joint Information

- Effusion/Corrosion

- Send RFQ

- About Industrial

- Aircraft Hose Store

- For Aircraft Owners

- For FBO/Mechanics

- Hose Kits

- Aircraft Hose Lookup

- Products

- PTFE Hose

- 666 Aluminum Fittings

- 666 Crimp Fittings

- 666 Reuseable Fittings Eng Bulletin

- AE246 Hi Pressure Hose Crimp

- AE246 Hi Pressure Hose Reusable

- AE313 Spiral Reinf Hose Eng Bulletin

- AE318 Wire Braid Hose Eng Bulletin

- AE645 Teflon Hose Eng Bulletin

- Brown Silicone Firesleeve Hose Eng Bulletin

- Convoluted Teflon Hose Eng Bulletin

- Firesleeve

- Rubber Hose

- Aircraft Metal Hose

- Other Hose Products

- Quick Disconnect Coupling

- 155-145 Series Coupling Catalog

- 3200 Series Coupling Catalog

- AA40 - 3900 Series Quick-Disconnect Coupling

- AEB189 - Self Sealing Coupling for Modular Hydralic Systems

- Break-away Coupling Catalog

- Ground Support Coupling Catalog

- Low Profile Couplings Catalog

- Low Profile Self Sealing Coupling Catalog

- Push-Pull Coupling Catalog

- TF100-32 Std Tube Sz and Variable Dia V-Band Coup

- Ultra-Mate TF100-5A

- Clamps, V Bands and Flanges

- AA29 - Aircraft Band Clamps

- AA33 - Stainless Steel Straps

- AEB195 - J13 and WJ13 Gasketless Tubes

- AEB197A - Conoseal (TM) Joints, Fittings and Conomate (TM) Couplings

- AEB201 - Exhaust Clamps

- AEB211 - LJ11 and J11 Joints

- DS100-6 - Exhaust Clamps

- TF100-26 - Aircraft Band Clamps

- TF100-27 - Stainless Steel Straps

- TF100-28 - J13 and WJ13 Gasketless Tubes

- TF100-30 - LJ11 and J11 Joints

- TF100-32 - Std Tube Sz and Variable Dia V-Band Coup

- PTFE Hose

- Markets

- Technical Information

- Cross-Reference

- About Aerospace

Measuring Aircraft Hose

Measuring and Gaging

Use seat-to-seat versus Overall Method because the

nuts will move and change the measured length.

Use the center line of fitting gage point on elbow

fittings.

Orientation – Hold hose in front of you with near

elbow pointing down towards six o’clock.

Measure counter-clockwise to rear fitting position.

Example: Rear fitting pointing at 9 o’clock is 270 degrees.

Fitting Size

Caution: Measure both ends! Hose fitting size may differ

from one end to the other

If you don’t have a thread gage, a hex wrench can be

used to help identify the fitting nut size.

Hose Size

Teflon hose and some rubber hose is measured as

tube size not true inside diameter. The hose is

specified by the outside diameter of the tubing. A

size -6 medium pressure Teflon hose is a nominal

3/8” with a .298 ID. The difference is important for

critical flow applications such as a turbo injector

lubrication line. Always check with the manufacturer

of the equipment before changing hose types.

- Products

- Applications

- Technical Information

- STAMPED

- Metal Hose Installation Guide

- Pressure Derating vs Temp

- Decimal Equivalent

- Thermal Expansion of Pipe

- Metric Conversion Factors

- Pipe Anchoring & Guiding

- Metal Hose Selection Factors

- Metal Hose Assembly Length Tolerances

- Metal Hose End Fitting Guide

- PTFE Hose End Fitting Guide

- Chemical Compatibility Chart

- Expansion Joint Information

- Effusion/Corrosion

- Send RFQ

- About Industrial

- Aircraft Hose Store

- For Aircraft Owners

- For FBO/Mechanics

- Hose Kits

- Eaton Product Search

- Products

- PTFE Hose

- 666 Aluminum Fittings

- 666 Crimp Fittings

- 666 Reuseable Fittings Eng Bulletin

- AE246 Hi Pressure Hose Crimp

- AE246 Hi Pressure Hose Reusable

- AE313 Spiral Reinf Hose Eng Bulletin

- AE318 Wire Braid Hose Eng Bulletin

- AE645 Teflon Hose Eng Bulletin

- Brown Silicone Firesleeve Hose Eng Bulletin

- Convoluted Teflon Hose Eng Bulletin

- Firesleeve

- Rubber Hose

- Aircraft Metal Hose

- Other Hose Products

- Quick Disconnect Coupling

- 155-145 Series Coupling Catalog

- 3200 Series Coupling Catalog

- AA40 - 3900 Series Quick-Disconnect Coupling

- AEB189 - Self Sealing Coupling for Modular Hydralic Systems

- Break-away Coupling Catalog

- Ground Support Coupling Catalog

- Low Profile Couplings Catalog

- Low Profile Self Sealing Coupling Catalog

- Push-Pull Coupling Catalog

- TF100-32 Std Tube Sz and Variable Dia V-Band Coup

- Ultra-Mate TF100-5A

- Clamps, V Bands and Flanges

- AA29 - Aircraft Band Clamps

- AA33 - Stainless Steel Straps

- AEB195 - J13 and WJ13 Gasketless Tubes

- AEB197A - Conoseal (TM) Joints, Fittings and Conomate (TM) Couplings

- AEB201 - Exhaust Clamps

- AEB211 - LJ11 and J11 Joints

- DS100-6 - Exhaust Clamps

- TF100-26 - Aircraft Band Clamps

- TF100-27 - Stainless Steel Straps

- TF100-28 - J13 and WJ13 Gasketless Tubes

- TF100-30 - LJ11 and J11 Joints

- TF100-32 - Std Tube Sz and Variable Dia V-Band Coup

- PTFE Hose

- Markets

- Technical Information

- Cross-Reference

- About Aerospace

SPECIALTY HOSE

CORPORATION

800-362-6533

Mon-Fri 8am-5pm EST

Hose Experts Standing By