Phone: 800-362-6533 • Local: 330-497-9650 • Fax: 330-497-0415

7800 Freedom Avenue NW • North Canton, Ohio 44720-6978

sales@specialtyhose.com | Cage Code 1S353

© 2024 Specialty Hose Corporation | All Rights Reserved

Website design and hosting by EmTech Enterprises

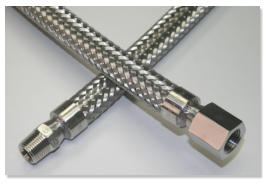

Metal Hose

Specialty Hose offers a complete line of Metal Hose - the most versatile of the hose products. • Materials: 304, 316, 321 Stainless Steel, Bronze, Inconel, Monel • Sizes: ¼” through 16” ID • Temperature Range: Cryogenic to +1500 Degrees Fahrenheit • Pressure Range: Up to 12000 psi working pressure

We accept the following

For additional information regarding our metal hose products, please contact us.

When should I consider metal hose for my application?

Generally, there are eight reasons to consider metal hose for your applications:

•

Temperature Extremes - If either the temperature of the media traveling through the hose, or the external conditions, are very hot or very

cold, metal might be the only material that can withstand the temperature.

•

Chemical Compatibility - Metal can handle a wider variety of chemicals than most other materials. If the hose is going to be exposed to

aggressive chemicals, either internally or externally, then you should consider using metal hose.

•

Permeation Concerns - Non-metal materials are susceptible to gases permeating through them and into the atmosphere. Metal does

not allow permeation. If it is important that a gas is contained within the hose, then you should consider using metal.

•

Potential for Catastrophic Failure - If a sudden failure of your hose could be catastrophic, you should consider using a metal hose.

Using metal could help to minimize the damage if your hose assembly should fail, since metal products generally develop small holes or

cracks when they fail, unlike other products which may develop larger holes of come apart completely.

•

Abrasion and Over-bending Concerns - To prevent abrasion and over-bending, a metal hose can be used as a protective cover over

wires or other hoses.

•

Fire Safety - Other product types will melt when exposed to fire while metal maintains its integrity up to 1200°F.

•

Achieving Full Vacuum - Under full vacuum, metal products maintain their shape while other product types may collapse.

•

Flexibility in Fitting Configuration - Virtually any type of fitting can be attached to metal products while other product types require

special shanks and collars.

WHEN?

CERTIFIED WELDING

SECTION IX ANSI B31.1 / B31.3

AWS D17.1

SPECIALTY HOSE

CORPORATION

Phone: 800-362-6533 • Fax: 330-497-0415

7800 Freedom Avenue NW • North Canton, Ohio 44720-6978

sales@specialtyhose.com | Cage Code 1S353

© 2023 Specialty Hose Corporation | All Rights Reserved

Website design and hosting by EmTech Enterprises

Metal Hose

Specialty Hose offers a complete line of Metal Hose - the most versatile of the hose products. Materials: 304, 316, 321 Stainless Steel, Bronze, Inconel, Monel • Sizes: ¼” through 16” ID • Temperature Range: Cryogenic -1500 Degrees Ferenhieght • Pressure Range: Up to 12000psi working pressure

When should I consider metal hose for my application?

Generally, there are eight reasons to consider metal hose for your

applications:

•

Temperature Extremes - If either the temperature of the

media traveling through the hose, or the external conditions,

are very hot or very cold, metal might be the only material

that can withstand the temperature.

•

Chemical Compatibility - Metal can handle a wider variety

of chemicals than most other materials. If the hose is going

to be exposed to aggressive chemicals, either internally or

externally, then you should consider using metal hose.

•

Permeation Concerns - Non-metal materials are susceptible

to gases permeating through them and into the atmosphere.

Metal does not allow permeation. If it is important that a gas

is contained within the hose, then you should consider using

metal.

•

Potential for Catastrophic Failure - If a sudden failure of

your hose could be catastrophic, you should consider using a

metal hose. Using metal could help to minimize the damage

if your hose assembly should fail, since metal products

generally develop small holes or cracks when they fail, unlike

other products which may develop larger holes of come apart

completely.

•

Abrasion and Over-bending Concerns - To prevent

abrasion and over-bending, a metal hose can be used as a

protective cover over wires or other hoses.

•

Fire Safety - Other product types will melt when exposed to

fire while metal maintains its integrity up to 1200°F.

•

Achieving Full Vacuum - Under full vacuum, metal products

maintain their shape while other product types may collapse.

•

Flexibility in Fitting Configuration - Virtually any type of

fitting can be attached to metal products while other product

types require special shanks and collars.

WHEN?

For additional information regarding our hose products, please contact us.

- Products

- Applications

- Technical Information

- STAMPED

- Metal Hose Installation Guide

- Pressure Derating vs Temp

- Decimal Equivalent

- Thermal Expansion of Pipe

- Metric Conversion Factors

- Pipe Anchoring & Guiding

- Metal Hose Selection Factors

- Metal Hose Assembly Length Tolerances

- Metal Hose End Fitting Guide

- PTFE Hose End Fitting Guide

- Chemical Compatibility Chart

- Expansion Joint Information

- Effusion/Corrosion

- Send RFQ

- About Industrial

- Aircraft Hose Store

- For Aircraft Owners

- For FBO/Mechanics

- Hose Kits

- Aircraft Hose Lookup

- Products

- PTFE Hose

- 666 Aluminum Fittings

- 666 Crimp Fittings

- 666 Reuseable Fittings Eng Bulletin

- AE246 Hi Pressure Hose Crimp

- AE246 Hi Pressure Hose Reusable

- AE313 Spiral Reinf Hose Eng Bulletin

- AE318 Wire Braid Hose Eng Bulletin

- AE645 Teflon Hose Eng Bulletin

- Brown Silicone Firesleeve Hose Eng Bulletin

- Convoluted Teflon Hose Eng Bulletin

- Firesleeve

- Rubber Hose

- Aircraft Metal Hose

- Other Hose Products

- Quick Disconnect Coupling

- 155-145 Series Coupling Catalog

- 3200 Series Coupling Catalog

- AA40 - 3900 Series Quick-Disconnect Coupling

- AEB189 - Self Sealing Coupling for Modular Hydralic Systems

- Break-away Coupling Catalog

- Ground Support Coupling Catalog

- Low Profile Couplings Catalog

- Low Profile Self Sealing Coupling Catalog

- Push-Pull Coupling Catalog

- TF100-32 Std Tube Sz and Variable Dia V-Band Coup

- Ultra-Mate TF100-5A

- Clamps, V Bands and Flanges

- AA29 - Aircraft Band Clamps

- AA33 - Stainless Steel Straps

- AEB195 - J13 and WJ13 Gasketless Tubes

- AEB197A - Conoseal (TM) Joints, Fittings and Conomate (TM) Couplings

- AEB201 - Exhaust Clamps

- AEB211 - LJ11 and J11 Joints

- DS100-6 - Exhaust Clamps

- TF100-26 - Aircraft Band Clamps

- TF100-27 - Stainless Steel Straps

- TF100-28 - J13 and WJ13 Gasketless Tubes

- TF100-30 - LJ11 and J11 Joints

- TF100-32 - Std Tube Sz and Variable Dia V-Band Coup

- PTFE Hose

- Markets

- Technical Information

- Cross-Reference

- About Aerospace

- Products

- Applications

- Technical Information

- STAMPED

- Metal Hose Installation Guide

- Pressure Derating vs Temp

- Decimal Equivalent

- Thermal Expansion of Pipe

- Metric Conversion Factors

- Pipe Anchoring & Guiding

- Metal Hose Selection Factors

- Metal Hose Assembly Length Tolerances

- Metal Hose End Fitting Guide

- PTFE Hose End Fitting Guide

- Chemical Compatibility Chart

- Expansion Joint Information

- Effusion/Corrosion

- Send RFQ

- About Industrial

- Aircraft Hose Store

- For Aircraft Owners

- For FBO/Mechanics

- Hose Kits

- Eaton Product Search

- Products

- PTFE Hose

- 666 Aluminum Fittings

- 666 Crimp Fittings

- 666 Reuseable Fittings Eng Bulletin

- AE246 Hi Pressure Hose Crimp

- AE246 Hi Pressure Hose Reusable

- AE313 Spiral Reinf Hose Eng Bulletin

- AE318 Wire Braid Hose Eng Bulletin

- AE645 Teflon Hose Eng Bulletin

- Brown Silicone Firesleeve Hose Eng Bulletin

- Convoluted Teflon Hose Eng Bulletin

- Firesleeve

- Rubber Hose

- Aircraft Metal Hose

- Other Hose Products

- Quick Disconnect Coupling

- 155-145 Series Coupling Catalog

- 3200 Series Coupling Catalog

- AA40 - 3900 Series Quick-Disconnect Coupling

- AEB189 - Self Sealing Coupling for Modular Hydralic Systems

- Break-away Coupling Catalog

- Ground Support Coupling Catalog

- Low Profile Couplings Catalog

- Low Profile Self Sealing Coupling Catalog

- Push-Pull Coupling Catalog

- TF100-32 Std Tube Sz and Variable Dia V-Band Coup

- Ultra-Mate TF100-5A

- Clamps, V Bands and Flanges

- AA29 - Aircraft Band Clamps

- AA33 - Stainless Steel Straps

- AEB195 - J13 and WJ13 Gasketless Tubes

- AEB197A - Conoseal (TM) Joints, Fittings and Conomate (TM) Couplings

- AEB201 - Exhaust Clamps

- AEB211 - LJ11 and J11 Joints

- DS100-6 - Exhaust Clamps

- TF100-26 - Aircraft Band Clamps

- TF100-27 - Stainless Steel Straps

- TF100-28 - J13 and WJ13 Gasketless Tubes

- TF100-30 - LJ11 and J11 Joints

- TF100-32 - Std Tube Sz and Variable Dia V-Band Coup

- PTFE Hose

- Markets

- Technical Information

- Cross-Reference

- About Aerospace

SPECIALTY HOSE

CORPORATION

800-362-6533

Mon-Fri 8am-5pm EST

Hose Experts Standing By